SAP MM module: What is, Material Management Process Flow

🚀 Smart Summary

SAP MM (Material Management) Module serves as a core component of SAP ERP, supporting organizations in managing material, inventory, and warehouse operations within the supply chain process, integrating logistics functions and enabling efficient business transaction execution.

What is SAP MM Module?

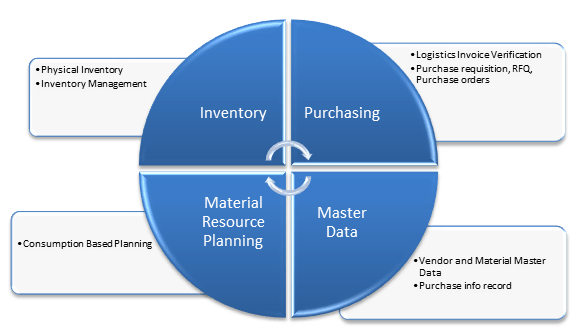

SAP MM (Material Management) Module is a SAP ERP component that helps organizations with material management, inventory management, and warehouse management in the supply chain process. It is a part of SAP ECC’s logistics functions which consists of several components and sub-components. The most prominent and widely used components are Master Data, Purchasing, and Inventory.

All of these components have their subcomponents that are essential in specific business processes, and all of the processes are executed by using transactions in SAP MM process flow.

Transaction (in SAP) means processing of certain information in order to complete business process requirement. For example, if you have purchased 10 pieces of litter buckets, you can perform particular transaction code (t-code) that will reflect those changes in SAP. Most of the business processes involve multiple SAP transactions to be accomplished and are spread over one, two or more modules.

Now in this SAP MM basics tutorial, let’s briefly talk about the various sub-modules in SAP Materials Management:

SAP MM – Master Data

Data stored in SAP R/3 is categorized as

- Master Data and

- Transactional Data.

Master data in SAP materials management is the core data that is used as a base for any transaction. If you are producing, transferring stock, selling, purchasing, doing a physical inventory, whatever your activity may be, it requires certain master data to be maintained.

Example of Master Data

- Material master data

- Customer master data

- Vendor master data

- Pricing/conditions master data

- Warehouse management master data (storage bin master data)

Learn more about Master Data

here

Purchasing

Purchasing is a component of SAP MM module, and its process can be roughly depicted in below diagram.

MRP (material resource planning) creates procurement proposal and later gets converted into Purchase Requisition. Next step is assigning a source to Purchase Requisition, and release of Purchase Requisition. The PR gets converted to Purchase Order, and upon goods receipt, an invoice receipt can be done to complete the purchasing process. Additionally, payment is processed (in FI module).

Learn more about Purchasing here

Inventory Management

Inventory management is used to manage the inventory of the goods. It is based on several key processes like

- Definition of movement types

- Reservations

- Goods issue

- Goods receipt

There are a number of functions and transactions used in the Inventory management processes.

Learn more about Inventory Management here

Pricing Procedure

Pricing procedure in MM module is a way to determine prices in purchasing documents. It gives us functionality to assign different calculation types for different needs. Defining a pricing procedure can be done by creating an access sequence, and assigning it to condition types. Access sequence tells the system where to look for the condition values.

Learn more about Pricing Procedure here

Features of SAP MM

- It can deal with both material management and inventory management.

- Ensures no shortage of material in the supply chain process.

- Helps to speed up material management and procurement activities.

- It helps to accelerate productivity and reduce costs while maintaining accommodations for frequent changes in a business environment.

- It helps organizations to deal with various business aspects like Procurement, Master data, Material valuation, Inventory management, Invoice verification, Material requirement planning, etc.

Business Benefits of SAP MM

The SAP Materials Management (SAP MM) module delivers measurable business value by optimizing procurement, inventory, and supplier management. Key benefits include:

- Streamlined Procurement: Automates purchase requisitions, orders, and approvals — reducing manual work and delays.

- Cost Efficiency: Controls spending with real-time visibility into material costs and vendor performance.

- Optimized Inventory: Tracks stock levels and movements to prevent shortages or overstocking.

- Seamless Integration: Connects with SAP FI, SD, and PP for unified financial and operational data.

- Enhanced Compliance: Maintains full audit trails and supports internal and external reporting.

- Supplier & Contract Management: Centralizes vendor data for better negotiation and supplier performance tracking.

- Real-Time Analytics: Enables faster, data-driven decisions with live dashboards and reports.

- Scalability: Supports multi-location, multi-currency operations for global enterprises.

- Higher Productivity: Automates repetitive tasks, freeing teams for strategic work.

Integration of SAP MM with Other ERP Modules

The SAP Materials Management (SAP MM) module is deeply integrated with other SAP ERP components, creating a seamless flow of information across key business areas. It connects with SAP FI (Financial Accounting) to automatically post financial entries such as goods receipts, invoices, and payments. Integration with SAP SD (Sales and Distribution) ensures that material availability aligns with sales orders and delivery schedules, preventing shortages or production delays. Through SAP PP (Production Planning), MM supports efficient manufacturing by ensuring materials are available when required.

Additionally, SAP MM integrates with SAP WM (Warehouse Management) for precise stock handling and storage optimization, while its link with SAP QM (Quality Management) ensures materials meet quality standards before production or dispatch. This interconnected structure eliminates data silos, enhances transparency, and streamlines decision-making. Ultimately, MM serves as the operational backbone—bridging procurement, inventory, finance, and production to enable efficient end-to-end supply chain management.