SAP APO Tutorial

Let’s start this SAP APO Tutorial with introduction of SAP APO:

What is SAP APO?

SAP APO is a key component of SAP to form a technical foundation for SAP modules. It is designed for high consistency in business processes, from order generation to production planning, and improving customer service while reducing costs. It is used for SCM (Supply Chain Management) to plan and execute supply chain processes. SAP APO stands for Advanced Planner Optimizer.

It is also known as APS (Advance Planning and Scheduling) tool.

Another important function of SAP APO Module is the SCC (Supply Chain Cockpit), it provides users with a graphical instrument panel for controlling and managing the supply chain. Various department of a company uses SCC like demand planners, strategic planners and production planners.

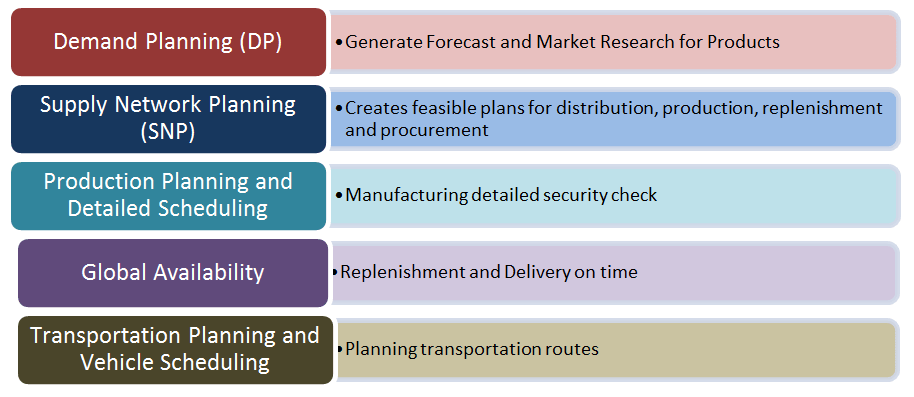

Important components of SAP APO used in Supply Chain

Following are components of SAP APO

Let’s look into them in detail!

A) APO Demand Planning

To run a successful business, market forecasting and planning is an important factor. “Demand Planning” is the art of understanding customers future demand and execution of such demand by corporate supply chain and business management. SAP Demand Planning provides advanced forecasting and demand planning tools that help companies to identify changes in demand as early as possible. Marketing and promotion are also done by the forecast of market demand using SAP APO Demand Planning.

B) APO Supply Network Planning

SNP (Supply Network Planning) integrates information on purchasing, manufacturing, distribution, and transportation so that tactical planning and decision can be made and implemented based on a single consistent model. Based on heuristic and mathematical optimization methods, SAP APO SNP ensures that organization or company meets the demand and performs activities like transportation, production, and warehousing resources.

For instance, the deployment function determines how and when the inventory should be deployed to distribution centers or warehouse.

C) Production Planning and Detailed Scheduling (PP/DS)

It allows manufacturing units to plan material and critical resources in an optimal fashion. A frequent demand for manufacturing units is to produce with limited resources.

PP/DS helps to analyze the lead time and resources required for production. You can reduce the inventory cost, increase on-time delivery performance, and reduce lead time for the product using SAP PPDS.

D) Global available-to-promise (global ATP)

The purpose of “Global available-to-promise” is to determine whether the requested product by the customer would be available on given or promised date. The process deals with improving, on-time delivery performance, planning system integration and sufficiently increasing stock to buffer inventories.

E) Transport Planning and Vehicle Scheduling (TP/VS)

By opting for best and short route of transportation, a company can save time, money and fuel spent on transporting and delivering goods. TP/VS provides transportation planner and schedules the routes at lower transportation cost. It offers functions like shipment consolidation, route determination, carrier selection, multi-pick, and multi-drop, etc.

Benefits of using SAP APO

- Increase in revenue

- Improve profit margins

- Reduce purchasing costs

- Reduce production and logistics costs

- Improved inventory management

- Improved Management

New & Advance features in SAP APO

On manifesting positive outcome of SAP APO System for business process, SAP APO is enhanced with extra features like

- SAP APO now enables transactional ERP systems in the supply chain to be interconnected. This will help in monitoring costs and pricing.

- It has become much faster than before as main memory of APO in SAP is upgraded to several gigabytes

- Now it comes with advanced optimization libraries like fast linear programming solver and efficient constraint propagation for scheduling problems.

- Scheduling is an important part of any business process. To deal with Scheduling, currently SAP APO uses the following approaches, Constraint Planning, Genetic Algorithm, and Repair Algorithm. The scheduling of a new version of SAP APO will be more accurate and schedule precisely at a particular time. With these advance SAP APO Modules, several supply chain planners can work simultaneously on one plan, each focussing on a small section of a larger supply chain.

Conclusion

Although SAP APO is no longer marketed as a separate solution, its functionality underlies SAP CRM, SAP E-Procurement, and SAP Supply Chain Management. Because of its open architecture, it is open to future enhancement like model functionality, higher degrees of parallelization and improved optimization algorithms.