In-Process Inspection SAP QM: CO01 & QA32

In-process inspection (time-based) is used for recording the result for an in-process quality check for the intermediate and finished product during the production process.

For example, inspection in every two hours, inspection per shift, etc. We will be discussing this moving forward.

The “Inprocess inspection” lot will have a reference/ link to a production order in SAP system.

The routing operation will contain the inspection characteristics which are needed to be inspected during the in-process checks.

Inspection lot will be generated at the time of production order release. The inspection type for in-process inspection is ’03’.

NOTE: This type of inspection will not control the inventory, but control the production process.

In-process inspection has following process steps, like

- Creation of inspection lots at process Order release

Inspection lot creation in SAP system will be generated automatically at the time of production order release.

- Listing of Inspection lot

To list Inspection lots, you may use the transaction code QA33. The search criteria can be,

- Material (s)

- Inspection lot creation date

- Inspection dates

- Plant

- Inspection type 03

- Assign Task list to inspection lot

Task list will be automatically assigned from the routing of material.

- Sample calculation

If sampling procedure is attached with the characteristics in the quality operation of the master recipe, the SAP system will automatically calculate the sample during the time of lot creation / plant assignment in case of multiple plans available for a material.

- Result recording

Result recording will be done against the inspection lot created against the production order.

All the characteristics will be shown in the SAP recording screen for input. The SAP system will give an f4 search for getting code values for attribute inspection.

For quantitative data, based on tolerance limit (upper and lower), the SAP system will propose the valuation. In both cases, the inspector can accept or reject the proposal (Manually).

- Usage Decision

When we make the usage decision, you decide whether to accept or reject the goods in the inspection lot based on the results of the inspection. Once you have made the usage decision, the inspection is completed. Stock posting is restricted to the in-process inspection.

How to create and release production Order

In this SAP transaction, we will create and release production order, which will trigger quality inspection lot in SAP system.

Step 1) From SAP Easy access menu, open Transaction code CO01, and enter the following details.

- Input the material code for which production order needs to be created.

- Input production plant in SAP screen.

- Enter your production Order type.

After filling in all the fields, click or press Enter to go to the next SAP screen.

Step 2) In the next SAP screen enter following details.

- Input the production quantity in SAP screen.

- Select “Current date” from the drop down box.

- Press “release” button to release the order.

Now, we will check if inspection lot has been generated by clicking “Assignment” tab and moved to the next SAP screen.

Step 3) In this SAP screen,

- You can see the inspection lot triggered on the release of production Order.

After checking the inspection lot, save the order by clicking save button.

How to do Result Recording

Step 1) From SAP Easy access menu, open Transaction code QA32.

Here, we will do in process inspection of the material and record the results against inspection specification.

- Enter Plant Code in SAP screen.

- Enter inspection lot origin as “03” which is standard SAP inspection type used for in-process inspection.

- Press Execute to display the list of inspection lot.

Step 2) In this SAP screen,

- You can see the inspection lot generated in earlier steps along with material

- Check the SAP system status as REL CALC which indicates that inspection specifications are copied in inspection lot and the sample size is calculated. We cannot see SPRQ status (Stock Posting) here, as it is not applicable/required to transfer quality stock to any unrestricted or other stock category for in process inspection.

- Press “Results” button and move to next SAP screen to do results recording.

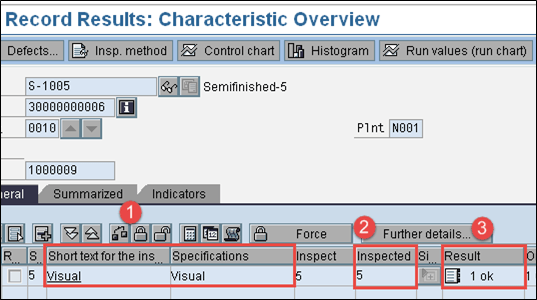

Step 3) In this SAP screen, you will see the result of inspection lot is generated.

- You can see the short text of the qualitative Master Inspection characteristics like “Visual.”

- You can see a sample size of “5” calculated automatically by the SAP system if sampling procedure is assigned in the inspection plan.

- Enter your actual results manually against the inspection specifications.

Press save button to save the inspection results.

How to do usage decision

Step 1) From SAP Easy access screen, open same Transaction QA32 with which we have done results recording in the previous step.

Here, we will do usage decision against inspection lot, and the decision is taken whether inspection lot should be accepted or rejected.

Follow the following steps in SAP screen,

- Enter Plant Code.

- Enter inspection lot origin as “03” which is a standard SAP inspection type used for in process inspection.

- Press execute button to display the list of inspection lot along with lot quantity.

Step 2) In this SAP screen,

- Press usage decision button to move to next screen

Step 3) In this SAP screen,

- Select UD code as “A” for acceptance of the lot and you can see the quality score as “100” based on Usage Decision code. You can see that there is no “Inspection lot stock” tab to do any stock posting as we saw in the raw material inspection.

Press save button to save the usage decision and hence in process inspection is completed.

In next SAP QM tutorial, we will see how to perform final Inspection after production.

Troubleshooting

- Inspection characteristics from routing data must be copied to inspection lot, without which we will not be able to do result recording and usage decision.

- If inspection characteristics are added in routing after inspection lot, then inspection lot will get CRTD status. In such case, we need to manually assign inspection specifications to change status from created (CRTD) to released (REL). After Inspection lot is released, then we can perform result recording and usage decision.

- The sampling procedure must be assigned in the inspection plan to do any result recording while the usage decision is done manually. We need to calculate the sample in the inspection lot.